Resident Engineering

Today, supplying components to OEM and TIER 1 customers is incredibly complex due to the countless regulatory, procedural, operational, and interpersonal interactions that continually arise in the course of business. Even simply responding fully to complex customer requests ends up involving multiple company departments, with a significant impact in terms of resources and manpower.

Aside from the direct and indirect costs incurred in supporting customers, finding satisfactory and timely solutions often presents objective difficulties.

By employing a Resident who is well-versed in plant dynamics, it is possible to establish excellent customer relationships, quickly and satisfactorily addressing all their requests.

The benefits of having a Resident on site encompass a broad spectrum of customer needs. Where the Resident has a thorough understanding of all stakeholders, their operating methods, and their actual needs, objectives are achieved and success is the order of the day.

From quality to logistics, from new product management to materials planning, from participation in official meetings to process investigations—just to name the most common tasks that every supplier can rely on to save time and money, the range of employment opportunities for Residents is truly vast.

Expediting

Ensuring that the components a company produces are of the highest possible quality and that customers are satisfied with the products they purchase. This is the task of Punto Netto's flying doctors.

Our flying doctors are a task force specialized in resolving technical and quality issues related to components manufactured by supplier companies and providing assistance at authorized workshops in their area. This team of "flying doctors" can resolve vehicle issues and technical defects both through remote support and direct visits to repair shops. Furthermore, our flying doctors can communicate directly and promptly with the manufacturer, reporting the technical issues handled and the most frequent defects encountered, and providing support to the Customer Care office in managing customer, legal, and senior management cases.

The term "flying" refers to the fact that these technicians travel frequently to reach their customers' locations or their own factories where they need to work. Typically, these technicians are employed by high-end component manufacturers and are also called "field technical specialists."

Fly Doctor

The need to monitor individual supplies to ensure the company's established quality standards are met has become increasingly important over the years.

For complex orders, monitoring project progress schedules assigned to individual suppliers allows the client not only to avoid inefficiencies but also to avoid penalties in the context of contract management.

Punto Netto's expediting activities, in line with current regulations, consist of monitoring the progress of a specific purchase order. The objective is to ensure that suppliers comply with order requirements, in terms of delivery times and quantities supplied, through constant and timely reminders.

Punto Netto opera nel rispetto delle specifiche ricevute dal cliente e secondo una pianificazione concordata con fornitore e cliente stesso, trasmettendo a quest’ultimo, al termine di ogni verifica, l’expediting report, un rapporto scritto dettagliato, corredato da documentazione fotografica, capace di attestare le verifiche ed i controlli effettuati e le eventuali segnalazioni di criticità sulla qualità della produzione e sui tempi di consegna della fornitura.

Dianalyzer / Canalyzer

CANalyzer is an analysis software developed by Vector, a world leader in the development of software and components for automotive electronics networking, widely used by automotive and electronic control unit suppliers to analyze data traffic in CAN-bus systems.

Its main field of application is electronic networking within a car and is mainly used in mechanical workshops to perform diagnoses on car control units, reprogram and update firmware versions and, if necessary, reset error codes.

Through the CAN bus and Vector software, Punto Netto's specialized technicians can update or reprogram loose components using specific flash tools for those specific electronic systems. Thanks to the CAN protocol, any electronic component can be interrogated by connecting directly to it. This also allows for intervention on parts stored in stock or on assembly lines to reprogram and update them.

Il software CANalyzerviene, pertanto, utilizzato dal personale qualificato Punto Netto su componenti di primo impianto quando queste devono essere verificate per scongiurare bug che possano pregiudicare il corretto funzionamento dei tanti sistemi presenti in una vettura oppure su componenti di ricambio obsoleti che si vogliono aggiornare (come navigatori satellitari e impianti di amplificazione stereo).

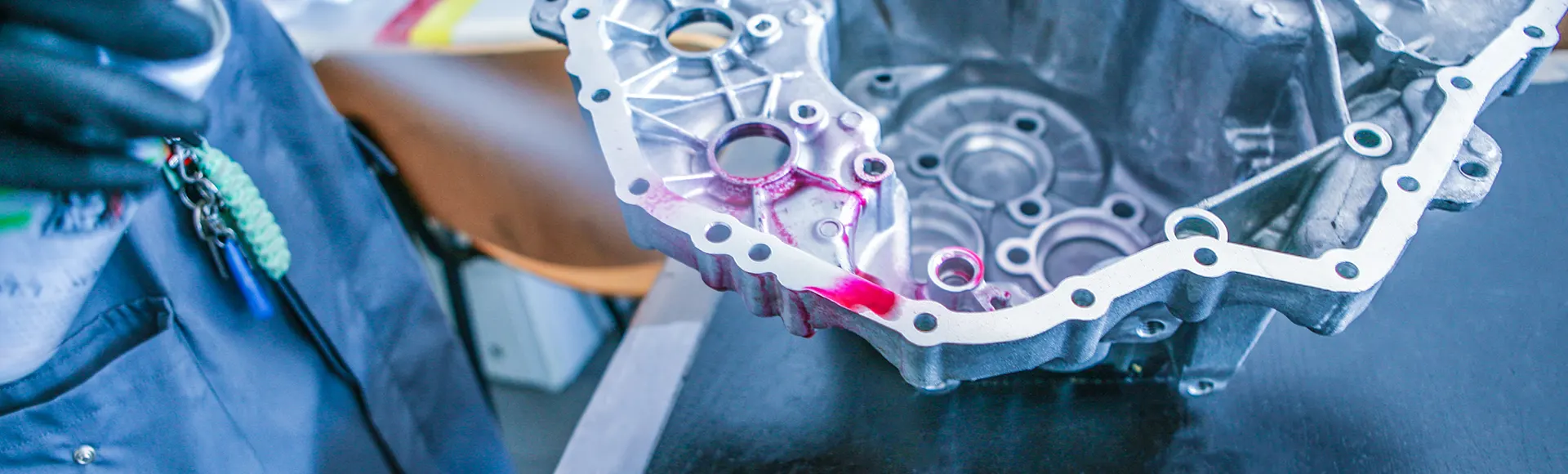

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.