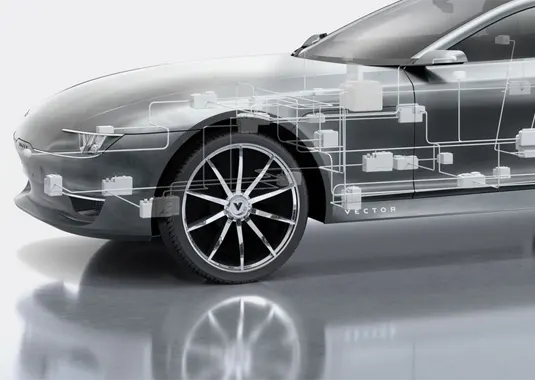

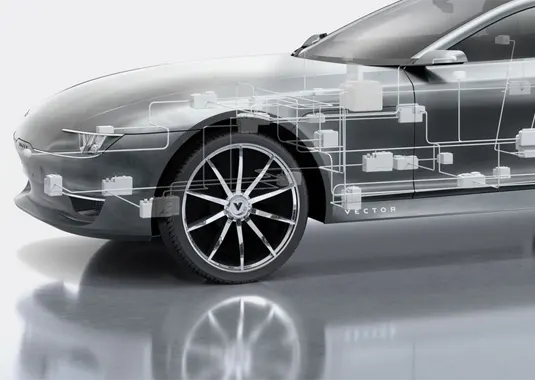

The CANalyzer is an analysis software from Vector, a world leader in the development of software and components for the networking of electronic systems on cars, widely used by suppliers of electronic and automotive control units to analyze data traffic in CAN bus systems.

Its main field of application is electronic networking inside a car and is used above all in mechanical workshops to diagnose car control units, reprogram and update firmware versions and, if necessary, reset error codes.

Through the CAN bus and the Vector software it is possible to update or reprogram the loose components using the specific flash tools for those specific electronic systems. Thanks to the CAN protocol it is possible to interrogate any electronic component by connecting directly to it. This also makes it possible to intervene on the pieces in the warehouse or on the assembly lines to reprogram and update them.

The CANalyzer software is therefore used on original equipment components when these must be checked to avoid bugs that could jeopardize the correct functioning of the many systems present in a car or on obsolete spare parts that need to be updated (such as satellite navigators and stereo amplification).

HOW DOES THE CAN PROTOCOL WORK?

The CAN, or the Control Area Network, is a network protocol that allows the circulation of information at high speed, just like with the LAN of a computer. The CAN protocol establishes the structure of the information packet that must travel on the network and a connector connects all the on-board control units of the car so that they communicate with each other, exchanging this information.

This type of network connection works in multimaster-multislave mode, i.e. the units connected to the connector, called nodes, work either as a master, sending and receiving information, or as a slave, receiving only information and providing it on request. The nodes do not have an address that identifies them and can, therefore, be added or removed without having to reorganize the system or a part of it.

The CAN protocol establishes the following information transmission criteria:

- - Start: start of the data package

- - ID: identifier of the message

- - Commands: type of message

- - Data: data packet transmitted

- - CRC: error detection code

- - End data, Acknowledge and End frame: closing information of the data packet

Today, vehicular communication networks are classified into the following three classes:

- - A: up to 10Kbps for bodywork applications (window lifters, central locking, etc.)

- - B: from 50Kbps to 125Kbps for dashboard applications (air conditioning, on-board instrumentation, etc.)

- - C: from 125Kbps to 1Mbps for engine compartment applications (engine management control unit, ABS / ESP, etc.)

WHAT IS DIANALYZER AND HOW DOES IT WORK?

DIANalyzer is an engineering diagnostic tool developed by FCA / Stellantis to run on Microsoft Windows platforms. It is used to interface with the control units and to perform a diagnosis of the electronic components already assembled and mounted on the individual cars.

Once these components have been queried, it is possible to reprogram or update the systems with DIANalyzer through the BIN files that have been produced by the same suppliers. Once the components have been updated, connect to the car's body computer to recognize the ECU being updated and refresh to re-establish proper communication between all the electronic systems connected to it.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.