- BROCHURE

- +39 0825 45 18 30

- ufficio@puntonetto.it

Menu

- Home

- Punto Netto

- Services

-

-

All services

-

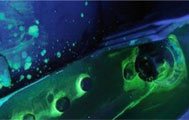

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.

-

Services

- Resident engineering

- Expediting

- Total quality management

- Testing and selection

- Sampling assistence

- Reworking

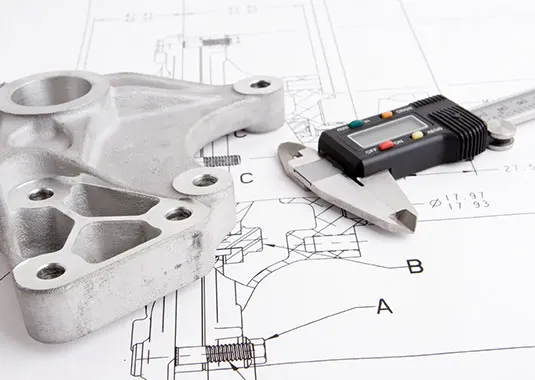

- Metrology room

- PPAP

- GP-12

- Flying-doctor

- Dianalyzer / Canalyzer

-

Additional services

- Wipe the drool

- Clean the oxide

- Cleaning

- Warehouses

- Impregnation treatment

- Scrapping

- Custom procedure

- Flash transportation

- Technical and Commercial Assistance

-

Application fields

- Automotive

- Renewable Energies

- Precision mechanics

-

-

- Inspection organism

- Non-destructive testing

- Make career

- News