News: Non-destructive surface checks performed with the Penetrating Liquid technique are widely used to check welds and are based on the ability to penetrate certain liquids, in fact, which enter the discontinuities of solid bodies such as cracks, cavities, folds and pores that emerge on the surface or just below and cannot be seen with the naked eye.

WHAT ARE NON-DESTRUCTIVE TESTS WITH PENETRANT LIQUIDS FOR

This type of non-destructive control () exploits the ability of some liquids to penetrate, by capillarity and not by gravity, into superficial and sub-superficial defects, especially in the field of tig and mig welding, and to highlight shapes and sizes.

Checking welds through the penetrating liquid technique is a fast, economical and accurate method for verifying any non-conformities on steels, copper and aluminum alloys, but also on glass and plastic. In addition, a liquid penetrant welds verification can be performed on any welded or cast component, regardless of the geometry of the component itself. Non-destructive tests with penetrating liquids, therefore, are one of the techniques most requested by our customers in Puglia, from our headquarters in Bari and in Campania (from our headquarters in Avellino and Naples, but more generally throughout Italy with mobile teams who travel around the country.

HOW DOES A CHECKING WELDS WITH PENETRANT LIQUIDS WORK

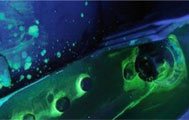

The control of welds and fusions with penetrant liquids (PT - Penetrant test) can be carried out in two ways: the color contrast method which allows you to observe any defects through a dark spot on a light background (generally red on White background); and the method with the fluorescent liquid where the contrast is once again light-dark (bright green on a purple background), but to understand the defect it is necessary to use an ultraviolet lamp

A liquid substance with low surface tension (and high wetting power) is deposited on the piece to be tested and a second substance (detector) highlights the capillary rise. Surface tension can be thought of as the force acting between molecules at the surface of a liquid.

SOME CONCEPTS RELATED TO THE PENETRANT LIQUID METHOD

Wettability:

It takes into account the ability of a liquid to expand on a surface and is therefore favored by a low surface tension. If the contact angle is less than 90 °, the surface is actually wetted by the liquid. If the contact angle is greater than 90 °, the cohesive forces existing between the molecules are greater than the adhesive ones, so the liquid takes on the appearance of disjoint drops.

Capillarity:

It is a phenomenon that allows a liquid to rise in very thin tubes. This phenomenon is explained by the existence of forces of attraction between the molecules of the liquid and the walls of the tube.

WHAT ARE THE PHASES OF A NON-DESTRUCTIVE TEST USING PENETRANT LIQUIDS?

The non-destructive tests based on the penetrating liquid technique consist of 6 distinct phases

1) Surface preparation;

2) Application of the penetrant liquid;

3) Removal of excess liquid;

4) Waiting for drying;

5) Application of the detector;

6) Observation of the indications.

Once the surface to be tested has been thoroughly cleaned, degreased and dried, the penetrant, usually red or fluorescent, is applied by dipping, brushing or spraying. The penetrant must form a uniform layer extending over the entire surface to be examined and must be left to act for a time sufficient to allow maximum absorption possible. The penetration time depends on the type of discontinuity to be detected and on the type of product used for the control.

The excess of penetrating liquid must be removed with a slightly soaked cloth, running water or with spray washing, taking great care not to eliminate the liquid trapped in the defects. Drying takes place extremely quickly. Then a thin layer of detector (white or fluorescent) is applied in order to absorb and attract towards the surface the penetrant trapped in the discontinuities.

CONTACT US FOR A QUOTE ON NON-DESTRUCTIVE CONTROLS WITH PENETRATING

Punto Netto, accredited by Accredia as a Type C Inspection Body and operating in compliance with UNI CEI EN ISO/IEC 17020:2012 through its highly qualified technical staff, which in turn has Level 2 certification in compliance with ISO 9712 standard, represents the best choice if you want to carry out accurate checks on tig and mig welds and evaluate any discontinuity of solid bodies such as cracks, cavities, folds and pores.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.

Among the many services provided by Equity Point stand out the non-destructive testing, with Penetrating liquids, Ultrasound and Magnetic Particle.